A whirling machine is a type of machine used in mechanical engineering to create rotating components. It is used to create items with exact dimensions and tolerances, such as worm gears machines, sprockets, and pulleys.

Read More:Whirling Machine 101: Everything You Need To Know

Whirling Machine Makes Economic Sense!

- Removal of the costly grinding procedure

- Cycle times are reduced by up to three times.

- Pitch accuracy and thread profiles

- Quick setup and changeover times

- Dry machining eliminates the need for pricey cutting fluid.

The Cutting Process and Chip Formation with Whirling Machine

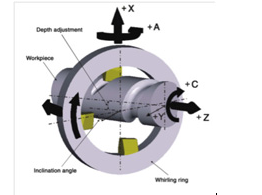

The cutting action is caused by a whirling machine ring revolving at high speed around a slowly rotating workpiece “C axis.” The thread pitch necessary is determined by rotating the workpiece and moving the “Z axis” tool head

The cutting angle of the tool head is adjusted about the “A axis” to match to the thread pitch angle. The eccentricity of the “X axis” controls the thread’s minor diameter. Right or left-handed threads can be machined by simply altering the “Z axis” travel direction. The spinning ring, however, constantly spins in the same direction as the workpiece, and it is the direction of travel that produces the appropriate left or right hand threads.

The cutting tools are held in place by the tool ring and move in relation to the workpiece. This cutting method produces perfectly comma-shaped pieces (see image 2). Although spinning is an interrupted cutting process, the smooth chip generation allows for the cutting of hardened material to 65 HRc and brittle material using carbide, CBN (Cubic Boron Nitride), or ceramic tools.

- nW Rotation of whirling tool

- T Depth adjustment

- nR Rotation of workpiece

- X Eccentricity

- SK Cutting circle

- K Comma shaped chip

Comparing Whirling with Milling

We must first consider the similarities between spinning and milling while cutting external threads. A whirling ring, like a milling cutter, contains numerous cutting teeth. During the noncontinuous cutting process, each cutting edge removes a given amount of material. But that’s where the parallels end.

Because of the progressive entry and exit of the insert cutting edges, whirling has a more advantageous cutting action, allowing for higher metal removal rates. Because of the smooth cutting process, radial pressure is reduced, resulting in less stress on the workpiece and insert. In addition, tool life is greatly increased, making the operation even more cost effective .

Whirling Machine process Video

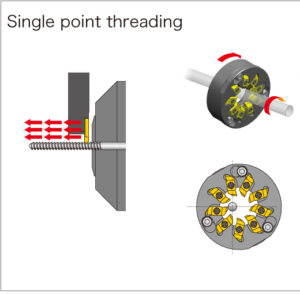

Comparison of single point and thread whirling process

The whirling head is tilted to a specified helix angle, the cutter is turned at high speed, the bar stock (c axis) is spun at low speed, and the pitch (z axis) is the feed in thread whirling.

The inserts shred the material, allowing for one pass thread formation.

Multi-lead thread Single pass forming examples

There are several process requirements for machining multi-lead tread shapes.

So please contact us to discuss mechanical parameters, spindle specifications, insert specifications, and tooling specifications.

Thread Geometry

The geometries shown above are approximated and vary depending on actual application details.

What is the difference between thread rolling and whirling?

Thread rolling is used as a regular technique because of the cost savings, improved surface polish, and longer service life. Thread spinning is better suited for small quantities and highly accurate threads with tight tolerances.

How does a thread whirler work?

Thread whirling is similar to thread milling in that the inserts are located on the inside of a cutting ring rather than the exterior of a milling tool. The thread whirling ring revolves around a cylindrical component to cut the thread in one pass.

What is thread milling?

Thread milling is the process of moving a thread mill around or within a workpiece to achieve a desired thread shape. Multiple radial passes while milling provide excellent chip control.