Ice fishing enthusiasts understand the significance of a well-crafted ice rod in their pursuit of the perfect catch. As the demand for high-quality ice rods continues to grow, the role of ice rod manufacturers becomes increasingly crucial. With a focus on innovation, technology, and uncompromising quality, ice rod manufacturers aim to revolutionize the industry.

This article explores the history, types, key features, materials, testing procedures, and future trends in ice rod manufacturing to provide an insightful overview for those seeking the perfect ice rod and a sense of belonging in the ice fishing community.

The History of Ice Rod Manufacturing

We will now delve into the history of ice rod manufacturing, tracing its evolution from early prototypes to the advanced designs of today. Ice rod manufacturing has come a long way since its inception, with countless innovations and advancements.

From simple wooden rods used by early ice fishermen to modern-day ice rods made from cutting-edge materials like graphite and carbon fiber, the industry has strived to create high-performance rods that cater to the needs and preferences of ice fishing enthusiasts.

Types of Ice Rods Offered by Manufacturers

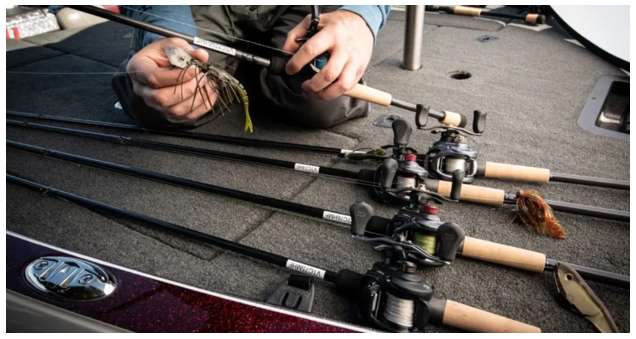

Ice rod manufacturers offer a wide range of options to cater to the diverse needs and preferences of ice fishing enthusiasts. Whether you are a beginner or an experienced angler, there is an ice rod designed for you. Manufacturers provide different types of ice rods, such as spinning rods, jigging rods, and tip-up rods. Each type has its own unique features and specifications, ensuring that every ice fisherman can find the perfect rod for their fishing style.

No matter what type of ice rod you choose, it is important to consider factors such as rod length, power, action, and materials used. These factors will determine the rod’s performance and suitability for different fishing conditions. The goal is to find an ice rod that matches your fishing style and helps you catch more fish on the ice.

Key Features to Consider When Choosing an Ice Rod Manufacturer

An important aspect to consider when choosing an ice rod manufacturer is the quality of their products and the range of options available. The quality of the rods will determine their durability, performance, and overall value for money.

A manufacturer that offers a wide range of options caters to different fishing preferences and conditions. By considering these key features, anglers can ensure that they choose a manufacturer that meets their specific needs and preferences. Now let’s delve into the importance of high-quality materials in ice rod manufacturing.

The Importance of High-Quality Materials in Ice Rod Manufacturing

When it comes to ice rod manufacturing, the use of high-quality materials is crucial for ensuring the overall performance and longevity of the rods. High-quality materials such as graphite, carbon fiber, and fiberglass offer strength, flexibility, and sensitivity, allowing anglers to detect even the subtlest of bites.

These materials provide durability, ensuring that the rods can withstand the harsh conditions of ice fishing. Investing in ice rods made with high-quality materials is essential for a satisfying and successful fishing experience.

Innovations in Ice Rod Manufacturing Technology

How have recent advancements in technology impacted the manufacturing of ice rods? These innovations have revolutionized the industry, providing ice rod manufacturers with new tools and techniques to create high-performance products. Here are three notable advancements:

- Precision machining: Computer-controlled machinery allows for precise shaping and cutting of rod components, resulting in enhanced performance and durability.

- Composite materials: Advanced materials such as carbon fiber and graphite composites provide strength and sensitivity without adding unnecessary weight.

- Nano-coatings: Cutting-edge coatings applied to the rod surface improve durability, reduce friction, and enhance sensitivity, providing anglers with a superior fishing experience.

How Ice Rod Manufacturers Test and Ensure Quality?

During the manufacturing process, ice rod manufacturers employ rigorous testing and quality control measures to ensure that their products meet the highest standards of performance and durability. These tests typically involve subjecting the rods to extreme conditions, such as freezing temperatures and high pressures, to assess their strength and resilience.

Manufacturers use specialized equipment to measure the rod’s flexibility, sensitivity, and weight distribution. This meticulous testing process ensures that ice rods are of the utmost quality and can withstand the harsh conditions of ice fishing.

The Future of Ice Rod Manufacturing: Trends and Predictions

Four major trends are shaping the future of ice rod manufacturing, and manufacturers must adapt to meet the changing demands of the market. These trends include:

- Advanced materials: Ice rod manufacturers are exploring new materials that offer increased strength, durability, and sensitivity, enhancing the overall performance of the rods.

- Customization options: Customers are seeking more personalized and unique ice rods, leading manufacturers to offer customizable features such as handle grips, reel seats, and rod lengths.

- Technological integration: The integration of technology into ice rods, such as smart sensors or GPS tracking, allows anglers to enhance their fishing experience and improve their success on the ice.

Frequently Asked Questions

How Long Have Ice Rod Manufacturers Been in Operation?

Ice rod manufacturers have been in operation for a significant period of time, with a history that spans back several decades. The industry has evolved and grown, adapting to changing technologies and customer demands.

Are Ice Rod Manufacturers Only Limited to Producing a Specific Type of Ice Rod?

Ice rod manufacturers are not limited to producing a specific type of ice rod. They have the expertise and resources to create a wide range of ice rods, catering to different preferences and fishing conditions, ensuring a diverse selection for anglers.

What Are Some Unique Features That Set Certain Ice Rod Manufacturers Apart From Others?

Some unique features that set certain manufacturers apart from others include innovative designs, use of advanced materials, customizable options, precision engineering, durability, and specialized features for different fishing techniques.

Conclusion

In conclusion, the ice rod manufacturing industry has a rich history and continues to innovate with new technologies and materials. Choosing a high-quality ice rod manufacturer is important for anglers looking to enhance their ice fishing experience.

By considering key features and ensuring the use of high-quality materials, anglers can find the perfect ice rod for their needs. As the industry evolves, trends and predictions indicate that ice rod manufacturing will continue to improve and meet the demands of ice fishing enthusiasts.

Also, Read The Following: Bulk PopSockets