What Is Laser Cladding?

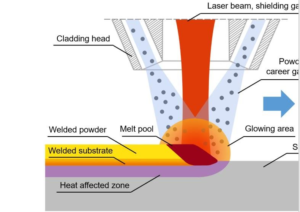

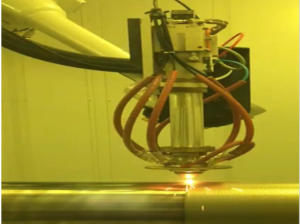

Laser cladding, also known as laser metal deposition, is a process for depositing one material on top of another. A stream of metallic powder or wire is fed into a melt pool formed by a laser beam as it scans across the target surface, producing a coating of the desired material.

The laser cladding method improves the surface properties of a part, such as wear resistance, and allows for the restoration of damaged or worn surfaces. One of the most accurate welding procedures is used to create this mechanical link between the base material and the layer.

Read More : Laser Cladding Powder Feeding Method Guide

Why is laser cladding an important manufacturing technology today?

By producing protective layers against wear and corrosion, laser cladding improves the performance of industrial items. Engineers may design parts with generic base metal alloys, which helps preserve natural resources. The component is then locally laser clad with a high alloyed material to provide the appropriate performance characteristics.

Laser cladding is also a method that is used to restore and remanufacture high-value components into their original shape. In addition to just fixing the shape of a part, choosing an additive material with superior wear characteristics than the original component improves service life and performance.

| Arc Welding | Thermal Spray | Hard-Chrome Plating | Laser Cladding | |

| Heat Input | High | Low | N/A (chemical process) | Low |

| Dilution Rate | 10 – 40% | N/A(mechanical bonding) | No metallurgical bond | <5% |

| Hardness (HV) | Relatively Low | <1000 | 800 – 1000 | >1000 |

| Distortion | High | Low | N/A | Low |

| Heat Affected Zone | Large and wide | Low | N/A | Low |

| Quality | Less durable | Full of pores and less durable | Prone to chipping and delamination | Highly dense and Long life |

| Pre/Post Treatments | Many | Many | Many | Few |

| Automation | Difficult | Difficult | Difficult | Easy |

| Coat Thickness | >0.020” | 0.020” – 0.040” | 0.002” – 0.006” | >0.020” |

Read More : Laser Cladding VS Thermal Spray

Coating of hydraulic cylinders for the mining industry

Laser coating of hydraulic cylinders in technological mining operations such as coal extraction is a rising business. The cylinder’s coating corrodes fast in the local climate, resulting in leaks, thus a replacement or fresh coating will be required.

Until recently, chromium plating was the dominant approach, but laser coatings will gradually replace it because of their greater endurance. The particular improvement in durability cannot yet be defined, although current data reveal a higher than 100% increase in lifespan.

Cutting Tools

Layers of laser clad materials can be utilized to protect saw blades, counter blades, disc harrows, and other cutting instruments from wear and corrosion while also offering enhanced cutting properties. Because of the lack of distortion in this technique, these tools remain straight while variable coating thicknesses may be obtained to meet needs. These coated tools may be used in a variety of industries, including construction and agriculture.

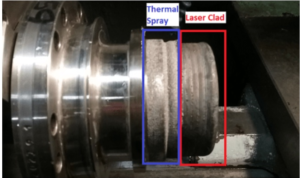

Proven Solution for Hot Mill Rolls used in Steel Making Industry

Rolling steel is a procedure that pushes the performance boundaries of the rolling equipment’s components. Roller and other component failures can be caused by abrasion wear, heat stress, and galling, resulting in downtime and quality concerns. Because of the wide temperature range, a high hardness, low friction solution is required.

Haitian Laser Machinery provides a tried-and-true solution for increasing the service life of hot mill rollers. Customers who have used our laser cladded carbide-based overlays have experienced a 6x increase in service life when compared to thermal spray or arc welding, resulting in decreased operating costs and downtime.

Bottom Punch/Magnet Dies

When producing magnets for motors, the magnet material is blended in a slurry and placed in a die. The slurry is then forced into the magnet die, forcing all of the water/contaminants out. These punches must have non-magnetic tips to avoid interfering with the polarity of the magnet. Furthermore, the dies are vulnerable to significant metal-to-metal wear.

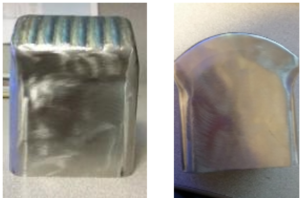

Stellite 6 was traditionally applied to the top surface using GTAW. The dilution line between the base material (W2 steel) and the substrate (Stellite 6) was, however, choppy, and the manual procedure was time intensive (about 1 hour each punch).

To boost efficiency, HaiTian developed an automated approach. A coaxial powder feed laser head was employed in the solution, and bespoke programming was used to map the clad/layer routes.

HaiTian was able to construct a Stellite 6 buildup with a very clear dilution line between the parent and clad material, as well as a cladding in 15-20 minutes rather than 1 hour. As a result, this automated approach significantly increased quality and efficiency.

Wind Turbine Centrifuge Hubs/Shafts

Wind turbine hubs and shafts wear owing to load fluctuation caused by changes in wind speed/intensity. Because of this wear, gearboxes might break early, resulting in expensive replacement costs.

HaiTian used laser cladding on worn hubs, journals, and shafts before machining them to original design specifications. Stainless steels (410 SS, 420 SS, 440 SS) were used as base materials. 420 stainless steel was used as the primary cladding material. Controlling the preheat and process conditions carefully guaranteed that the clad material was defect-free and had similar/improved characteristics to the base material.

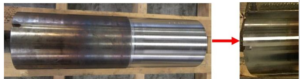

Steel Mill Rods

Steel mill rods are components that are frequently worn. Typically, the wear is minimal yet sufficient to render the rod unusable. IBC Coatings Technologies coat worn rods with lasers. The base material was a high strength steel (4140), and the overlay was 431SS martensitic stainless steel to increase the wear resistance of the substrate.

What Type of Laser Is Used in Laser Cladding?

1. Fiber Lasers

Fiber lasers, which use optical fibers to create laser beams, are well-known for their efficiency and dependability.

2. Diode Lasers

Diode lasers are a type of laser that produces laser radiation via a semiconductor. Diode lasers, which vary in wavelength, power, and fiber type, are used in two types of prostatectomy procedures

3. CO2 Lasers

Carbon dioxide lasers, often known as CO2 lasers, generate laser beams using a gas mixture and are ideal for cladding greater regions.

4. Nd:YAG Lasers

Solid-state crystals are used to create laser beams in neodymium-doped yttrium aluminum garnet lasers. They are adaptable to a variety of cladding applications.