Automated processes are revolutionizing industrial processes in this era of technological advancement. Manufacturing is becoming a seamless and efficient marvel thanks to innovative technologies. Labor-intensive tasks are a thing of the past.

Join us as we explore the captivating world of automation in manufacturing process automation 2023, uncovering its incredible benefits that will leave you in awe. Buckle up for an electrifying journey into a realm where productivity soars, quality skyrockets, and human potential is unlocked like never before!

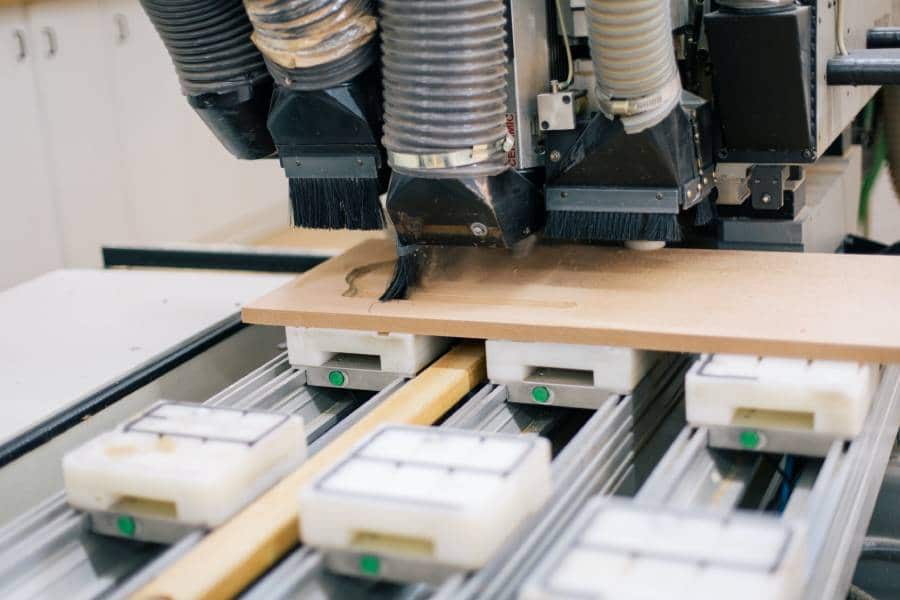

Types of Automation in Manufacturing: Robotics, AI, and IoT

Manufacturing process automation has revolutionized the way industries operate, making processes more efficient and cost-effective.

- Customization and Flexibility: The integration of robotics, AI, and IoT allows for more flexible and customizable manufacturing processes. AI algorithms can adapt to changing demands and optimize production schedules in real time. This agility enables manufacturers to respond quickly to market trends and customer preferences.

- Energy Efficiency: Automation, when designed with sustainability in mind, can contribute to energy efficiency. AI algorithms can optimize energy consumption based on real-time demand, and IoT sensors can provide insights into energy usage patterns. This not only reduces operational costs but also aligns with environmental goals.

- Human-Machine Collaboration: As technology advances, the focus is shifting towards creating environments where humans and machines collaborate seamlessly. While robots handle repetitive and strenuous tasks, human workers can engage in more complex decision-making, problem-solving, and creative aspects of manufacturing. This collaboration enhances overall productivity and job satisfaction.

- Supply Chain Visibility: IoT plays a crucial role in enhancing visibility across the entire supply chain. From tracking raw materials to monitoring the status of finished products during transit, IoT devices provide real-time data. This transparency is invaluable for optimizing inventory management, reducing lead times, and ensuring timely deliveries.

- Predictive Quality Control: The combination of AI and IoT enables predictive quality control measures. By continuously monitoring and analyzing data from production processes, manufacturers can detect deviations from quality standards in real time. This proactive approach minimizes defects and ensures that only high-quality products reach the market.

- Cybersecurity Measures: As technology evolves, addressing cybersecurity concerns becomes paramount. Manufacturers need robust cybersecurity measures to protect sensitive data and ensure the secure operation of interconnected systems. Investing in cybersecurity infrastructure is crucial to safeguard against potential threats.

- Skill Development: As automation grows, workforce skills must shift toward programming, data analysis, and system maintenance. Ongoing training is crucial for adapting to the changing technological landscape.

Embracing advanced technologies in manufacturing enhances efficiency and contributes to a sustainable, innovative future. The convergence of robotics, AI, and IoT is reshaping the industry, offering a significant competitive advantage to those who embrace these changes.

Benefits of Automation in Manufacturing

Automation has revolutionized the manufacturing industry, bringing numerous benefits to businesses worldwide. By integrating advanced technologies and processes, automation streamlines operations and enhances productivity. Here are some key advantages of using automation in the manufacturing process.

● Increased Productivity

Automation eliminates repetitive manual tasks, enabling faster and more efficient machine performance. It ensures continuous operation 24/7, leading to higher output rates with fewer errors. Automated systems contribute to improved accuracy and precision, collecting real-time data for monitoring and optimization, positively impacting operational efficiency and competitiveness.

● Improved Quality Control

Automation enhances consistency through precise inspections, reducing variability and boosting confidence in product quality. Real-time monitoring with sensors and cameras detects deviations, preventing defective products from reaching customers. Automation’s advanced algorithms facilitate swift defect detection during production, enhancing overall product quality, and ensuring compliance with industry regulations.

● Cost Savings

Automation eliminates manual labor in repetitive tasks, reducing human error and cutting labor expenses. The continuous operation of automated systems enhances production efficiency, minimizing overhead costs associated with idle time. It contributes to better inventory management, preventing overstocking or understocking, optimizing inventory levels, and reducing material wastage, ultimately leading to substantial cost savings across various industries.

● Safety and Risk Reductions

Automation minimizes manual labor, eliminating dangers associated with hazardous environments and reducing the risk of injuries. It ensures consistent adherence to safety protocols and allows early detection of abnormalities through real-time monitoring, preventing safety risks from escalating. Automation also mitigates financial and reputational risks through improved quality control, reducing the likelihood of defective products causing harm.

● Streamlined Supply Chain Management

Automation, utilizing technologies like robotics, AI, and IoT, has transformed supply chain management. It improves inventory control with real-time tracking, optimizes production planning, and reduces costs related to overstocking or shortages. Increased visibility across the supply chain facilitates quick and informed decision-making.

Automation enhances communication between stakeholders, reducing delays and errors in handling orders and shipments, leading to greater productivity, cost savings, and enhanced customer satisfaction for manufacturing businesses.

Challenges and Limitations of Automation in Manufacturing

There are many benefits to automation for the manufacturing industry, but it also comes with certain challenges and limitations. Return on Investment (ROI) Analysis:

- Change Management and Communication: Effectively managing change is key to overcoming employee resistance. Clear communication about the benefits of automation, the company’s commitment to employee development, and the creation of a positive work environment can help build support among the workforce. Involving employees in the decision-making process can also foster a sense of ownership and collaboration.

- Predictive Maintenance Solutions: To address maintenance challenges, implementing predictive maintenance solutions can be beneficial. IoT sensors and AI algorithms can monitor equipment health in real-time, predicting potential issues before they lead to downtime. This proactive approach minimizes disruptions and ensures that automated systems operate at peak efficiency.

- Human-Centric Design: Designing automation systems with a focus on human-machine collaboration is crucial. Instead of entirely replacing human roles, automation should be seen as a tool to enhance human capabilities. This approach not only preserves the value of human interaction in the production process but also fosters a positive work culture.

- Continuous Training and Upskilling: Establishing ongoing training programs is essential to address the skills gap and ensure that employees can adapt to changing roles in an automated environment. Offering opportunities for upskilling and reskilling demonstrates a commitment to employee development and helps build a skilled workforce capable of managing and maintaining automated systems.

- Cybersecurity Best Practices: Cybersecurity should be a top priority in any automated manufacturing environment. Implementing robust cybersecurity measures, including encryption, regular software updates, and employee training on cybersecurity best practices, can mitigate the risks associated with connected devices and data exchange.

- Collaboration with Experts: Seeking guidance from automation experts and consulting with industry peers who have successfully implemented automation can provide valuable insights. Learning from others’ experiences and best practices can help navigate the complexities of integrating automation into manufacturing processes.

By addressing these challenges proactively and adopting a holistic approach to automation implementation, manufacturers can maximize the benefits while mitigating potential risks and disruptions. It’s a journey that requires careful consideration of technological, organizational, and human factors for long-term success.

Conclusion: The Future of Automation in the Manufacturing Industry

In summary, automation holds the key to the future of manufacturing by providing enhanced productivity, quality control, cost savings, safety, and supply chain management. Despite challenges, the long-term benefits make it necessary for maintaining global competitiveness. This transition promotes growth, innovation, and a seamless partnership between humans and robots, paving the way for a new era of industrial progress with endless possibilities in various industries.

Also, Read The Following: ChatGPT