Welcome to the world of manufacturing, where precision and efficiency reign supreme! Today, we delve into the fascinating realms of die casting – a foundational technique that brings intricate metal components to life. Among its variations, two methods stand out: gravity casting vs die casting.

While they may sound similar, these techniques hold key differences that can make or break your production process. So buckle up as we weigh their pros and cons, dissect their mechanics, and uncover which one will best suit your specific manufacturing needs. Get ready for a riveting exploration into the difference between gravity casting vs die casting!

Explanation of Pressure Die Casting

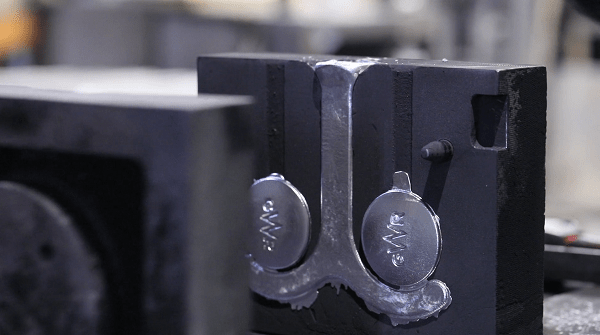

Let’s dive into the fascinating world of Die Casting and explore the intricate process of Pressure Die Casting. This method involves injecting molten metal into a reusable mold, under high pressure, to create complex shapes with excellent dimensional accuracy.

#1: Process and Equipment

Pressure Die Casting

Pressure die casting involves rapidly injecting molten metal into a steel mold under high speed and pressure. The mold, or die, is designed to shape the metal into the desired final product using hydraulic or mechanical force to drive the molten metal into the die cavity. This process requires specialized equipment, including a machine with two halves—a dedicated injection unit for holding the molten metal and a clamping unit to secure the mold during injection. Various components like pistons, cylinders, and cooling systems are integrated into the machine to ensure efficient operation.

Gravity Die Casting

Gravity die casting relies on gravity, not external force, to fill the mold with molten metal. Liquid metal is poured into a durable tool called a gravity die or permanent mold, utilizing gravity for consistent material distribution within the mold. Equipment for gravity die casting includes a furnace for melting metal alloys and ladles or robots for pouring into molds, typically made of iron or steel and reusable multiple times before replacement is required.

Both gravity casting vs die casting have distinct processes and equipment requirements tailored to specific production needs in various industries. Understanding these differences is crucial for making informed decisions when choosing between the two methods for manufacturing purposes.

#2: Advantages and Disadvantages

Advantages of Pressure Die Casting

- Precision: Pressure die casting excels in creating intricate shapes with high precision and tight tolerances.

- Speed: It allows for rapid production cycles, resulting in shorter lead times and increased efficiency.

- Surface Finish: Parts produced through pressure die casting have excellent surface finishes, reducing the need for additional finishing operations.

- Mechanical Properties: Pressure die casting produces parts with superior mechanical properties, such as strength and durability, making them suitable for demanding applications.

Disadvantages of Pressure Die Casting

- High Initial Costs: Setting up the necessary equipment and molds for pressure die casting involves significant initial costs, which can be challenging for small-scale manufacturers or those with budget constraints.

- Risk of Porosity: High pressures in pressure die casting can lead to porosity or air entrapment if not carefully controlled, affecting part quality and integrity.

- Inconsistent Wall Thickness: Maintaining consistent wall thickness across complex geometries can be challenging in pressure die casting, leading to uneven cooling rates and potential defects like warping or distortion.

Despite its drawbacks, pressure die casting remains an efficient method for producing high-quality metal parts with speed and precision.

Understanding Gravity Die Casting

Process and Equipment

Gravity casting vs die casting are two distinct methods for producing metal parts:

- Pressure Die Casting uses high pressure to inject molten metal into a steel mold (die), ensuring intricate details and precise dimensions. Specialized equipment like furnaces, plungers, and cooling systems are required.

- Gravity Die Casting, on the other hand, relies on gravity to fill permanent metallic molds with molten metal. It involves pouring the metal, guiding it through cavities with gravity, and cooling it. This process requires simpler equipment compared to pressure die casting.

Understanding these differences is essential for choosing the right method for specific production requirements.

Advantages and Disadvantages

When choosing between gravity casting vs die casting, it’s essential to evaluate their respective pros and cons.

Pressure Die Casting

- Precision: Ideal for crafting intricate shapes with precision and tight tolerances.

- Speed: Enables rapid production for mass quantities with shorter cycle times.

- Initial Cost: High setup costs due to specialized equipment and tooling.

Gravity Die Casting

- Suitable for Large Parts: Excellent for producing large and heavy parts with good structural integrity.

- Surface Finish: Delivers a fine surface finish without the need for additional finishing processes.

- Limitations on Complex Shapes: Less suitable for complex or thin-walled parts with intricate details due to longer cycle times.

The choice depends on specific production needs, whether prioritizing speed and precision (pressure die casting) or cost-effectiveness with quality (gravity die casting). Both methods have their advantages and disadvantages, and understanding these differences is key to making an informed decision.

Key Differences Between Pressure and Gravity Die Casting

In die casting, two main methods exist: pressure die casting and gravity die casting, each with distinct differences impacting their applications and outcomes.

- Process and Equipment: Pressure die casting employs a machine to inject molten metal into molds at high speed and pressure. Gravity die casting, on the other hand, relies on gravity alone to pour molten metal into stationary molds.

- Advantages and Disadvantages: Pressure die casting offers speed, precision, fine surface finish, and intricate shape capabilities. However, it requires expensive equipment setup and suits large-scale production.

- Gravity die casting has lower tooling costs, less porosity, and better mechanical properties but involves longer cycle times and is less suitable for complex shapes or thin-walled components.

Choosing between them depends on your project’s specific needs.

Choosing the Right Method for Your Production Needs

Choosing the right method for your production needs is important in ensuring optimal results and efficiency.

Factors to Consider

When choosing between gravity casting vs die casting for your production needs, it’s vital to consider several factors. Each method comes with its own set of pros and cons, so a thorough evaluation is essential.

- Complexity of Product: Pressure die casting is suitable for intricate designs with complex shapes and thin walls due to its precision. Gravity die casting is better for simpler designs with thicker walls.

- Cost-Effectiveness: Pressure die casting involves higher upfront costs, making it more economical for larger production runs. Gravity die casting has lower initial expenses and can be cost-effective for smaller batches.

- Material Compatibility: Pressure die casting accommodates a wider range of materials, while gravity die casting is generally limited to non-ferrous metals like aluminum and bronze.

- Production Volume: Pressure die casting is ideal for high-volume production with rapid cycle times. Gravity die casting is suitable for smaller batch sizes or prototypes.

- Lead Times: Pressure die casting typically requires longer setup times due to mold preparation and machine calibration. Gravity die casting offers quicker setup times.

By considering these factors, you can make an informed decision on whether gravity casting vs die casting is the best fit for your specific production requirements.

Applications of Each Method

Having explored the processes, equipment, advantages, and disadvantages of both pressure die casting and gravity die casting, let’s now delve into their respective applications.

- Pressure Die Casting: With its high-speed production capabilities and exceptional dimensional accuracy, pressure die casting finds widespread use in industries such as automotive manufacturing. It proves ideal for crafting complex parts with intricate details, like engine components or transmission parts. Additionally, pressure die casting plays a crucial role in sectors such as aerospace, electronics, and consumer goods where precision and consistency are paramount.

- Gravity Die Casting: Conversely, gravity die casting boasts its unique applications. Its proficiency in producing larger castings with superior surface finish makes it a fit for industries like furniture manufacturing or architectural fittings. Gravity die casting excels in creating heat sinks for electronic devices or decorative pieces requiring intricate details.

Also, Read The Following: best money-making apps